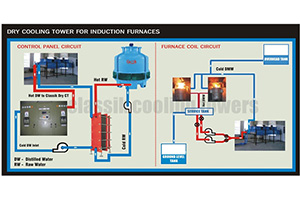

Dry Cooling Towers

- The fluid coils of international standards are designed and selected through software providing accurate data on thermal transfer rate based on which they are manufactured.

- The tower designed incorporates the shell and tube designed with copper tubing and aluminium foil fins.

- The water losses are 0.01% since, the circuits are of the closed loop type and the towers are most space saving / energy efficient once. They are best suited for applications such as Furnace coil water cooling, D/G Sets, Compressors.

- The fans are of aluminium die cast with adjustable pitch and are individually tested for different flow rates. They are all dynamically balanced. Since, the complete fan is of Aluminium Alloy / Plastic it does not corrode when used in out door applications.

- Dry cooling towers are in a single unit can be provided in capacities from 1000 kw to 1500 kw and they can be multiplexed to reach many thousand or kilowatts.

Air-Cooled fluid coolers are produced in our modern plant of International standards, The design. selection, construction of air-cooled fluid coolers are through software which gives us a very accurate data on thermal transfer rate, based on which we manufacture towers.

The Tubes and fins are of Copper and Aluminium MOC, respectively. Copper tubes of 5/8″ OD are level wound and the joints are minimized. The return bends are precision die formed to ensure the thickness is maintained with uniformity. All joints are tested for pressure and leak.

The headers (Inlet & Outlet) are of heavy class steel and the brazed connections are strengthen for long lasting.

All structural are of HDG Steel and casings in FRP to ensure rust prevention and durability. The water duty coil are provided with suitable vent connections at the highest point and drain connection at the lowest point.

The motors are of the ‘F’ class type, IP-55 protected and specially designed for outdoor applications. Fans are of the axial flow type, driven by motor.

The fans are of aluminium die cast with adjustable pitch and are individually tested for different flow rates. They are all dynamically balanced. Since, the complete fan is of Aluminium Alloy / Plastic it does not corrode when used in out door applications.

- Eliminates Scale-formation

- Eliminates Contamination of air

- Eliminates Frequent maintenance

- Eliminates FRP Cooling Tower

- Eliminates make up water after the first fill

- Eliminates raw water Tank and Pumps.

- Eliminates Moving parts except fan & motor

- Eliminates Mixing of dust / dirt / fly ash with Water

- Eliminates PHE at Furnace & Coil circuit

- Eliminates descaling, fungus cleaning Chemicals

- Eliminates water softening plant & chemicals

- Eliminates Heat exchanger headaches at primary circuit

- Eliminates maintenance cost, reduces power cost & saves earth

- Eliminates break down and Production loss

- Power generation units (Mega watts projects)

- Steel Casting Foundries /Steel Plant (MS Ingot / Billet Mfg)

- Diesel / Gas generators

- Air compressor cooling / after cooler / inter cooler / jacket cooler.

- Heat Treatment Furnaces (Forging Unit)

- Special process applications

- Rubber Industries

Cooling Tower

Quality